Preserving history: Restoring the iconic Elizabeth Tower

Our Special Projects team worked meticulously to restore the Elizabeth Tower and bring back its former glory.

Nick Sturge, Project Manager, Sir Robert McAlpine Special Projects, and Shauna Farrell, Chief Engineer, Sir Robert McAlpine Special Projects, share the "once in a lifetime" experience of working on the restoration of the Elizabeth Tower.

For over 160 years, the Elizabeth Tower, also known as Big Ben, has stood tall as the nation's timekeeper. However, the passage of time, combined with the adverse effects of pollution, weather, and war, had taken its toll on this iconic London landmark. It was clear that significant restoration work was needed to preserve this landmark for future generations and our Sir Robert McAlpine Special Projects team, renowned for its expertise in handling complex heritage projects, was on hand to take it on.

When it was first built in 1859, the Great Clock at the top of Elizabeth Tower was the largest and most accurate in the world. When we began work on the Tower in 2017, however, war, pollution and time had all taken their toll. The clock dials suffered from bomb damage during the Second World War, and repairs done in the 1950s failed to fix all the issues. And over the years, panes of glass from the dials had broken and been replaced with poor imitations that didn’t match the original colour.

The team tackling the restoration of the Tower was determined to fix this – and to return the dials to their former glory. Parliament’s Architecture and Heritage team worked with paint experts at Lincoln University to analyse over 160 years’ worth of paint applied to the clock tower. Together, they identified six different colour schemes that had been used over the years, comparing these to the original drawings for the building in order to unearth what the clock dials looked like a century and a half ago.

With the original colour scheme identified, a team of specialist stained glass experts from South London worked to find a perfect match for the Prussian blue and gold on the dials and clock hands. All 1,296 pieces of glass in the clock dials were then replaced by hand – with each person working on the project given the opportunity to install one of the precious mouth-blown segments.

The pride of everyone who worked on the Tower was evident throughout the project. With each team member aware that this might go down in their memories as the highlight of their career, the atmosphere on site was electric.

Every person’s passion for their work was tangible in how they performed their activities and supported one another. It was a true privilege for our site team to work on this site and contribute to the nation’s history.

So striking was the scaffold we erected at Elizabeth Tower that it was immortalised in the design of the bottle of the iconic British condiment HP Sauce.

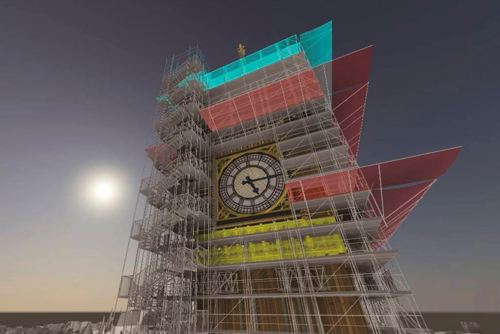

Designed by our in-house practice McAlpine Design Group and supply chain member PHD Access, the scaffold stood 98m high and enveloped almost the entire structure – but, in order to protect the Tower from further damage, it needed to be entirely freestanding.

As such, it was an enormously complex piece of temporary works, featuring 24,000 separate elements and taking six months to construct in an operation that involved 320 individual vehicle movements.

Our digital construction expertise proved invaluable when it came to managing such complexity. To help us coordinate the design of this feat of engineering, we created a detailed 3D model, in line with the public sector aspiration of achieving BIM level 2 on construction projects, to give everyone an understanding of how it would work and where each component would be installed.

This became particularly important at the level of the belfry, where the scaffold was to pass through the Tower’s cast iron frame once its roof tiles had been removed.

True team spirit was on display at the Elizabeth Tower. With everyone committed to making this scheme a project to remember, they worked tirelessly towards their common goal, anticipating each other’s needs and having each other’s backs. Over the course of the five years spent together on the site, they got to know each other so well that it made solving problems and planning complex tasks easy.

For many on the Elizabeth Tower project team, this was one of the most rewarding experiences of their career.

The scheme was a roaring success on multiple levels: the work was done to exceptional standards of quality, with an excellent safety record, and the project has been shortlisted for, and won, a number of prestigious industry awards.

For our high-performing professionals, seeing all their hard work pay off to such an extent is a feeling they’ll never forget. Photo by ©UK Parliament Mark Duffy

This prestigious project attracted specialists from every corner of the country and all over the world.

Around 600 people contributed to the restoration effort, including consultants, security personnel and fire strategy experts as well as our own colleagues – a coming-together of skill and expertise that was truly inspiring for everyone involved.

The site team at Elizabeth Tower consisted of around 90 people at its peak. With everyone working together in a space just 12m square, there were plenty of opportunities to learn from each other.

In such close quarters, large contractors and individual artisans were able to swap experience and expertise, exhibiting a level of care for their work that inspired everyone who came in contact with them.

This triggered a passion for the heritage sector, and several of our team members have gone on to obtain qualifications in historic construction and manage other heritage projects – demonstrating that the Elizabeth Tower scheme has left a truly enduring legacy. Photo by ©UK Parliament Jessica Taylor.

It’s not often you see such a concentration of skill and passion on a construction project as there was on Elizabeth Tower. The specialist artisans working on the scheme had been honing their craft for years or even decades –this project was the culmination of a career spent contributing to some of the best-known buildings in the nation.

One such person was John Reyntiens, the specialist responsible for crafting the handblown pieces of glass in the Tower’s four clock dials. The son of Patrick Reyntiens, himself a notable stained glass artist, John has restored glazing at the Speaker’s Residence, the House of Lords, Westminster Hall and Windsor Castle, and has installed glass artwork at Shakespeare’s Globe, Southwark Cathedral and two Cambridge colleges, among many other illustrious commissions. Photo by ©UK Parliament

With three decades of traditional glasswork under his belt, he’s a sterling example of the kind of expertise it took to bring Elizabeth Tower back to life. Another such example is the Cumbria Clock Company, which has spent 33 years restoring some of the UK’s most iconic timepieces.

They maintain the country’s oldest clock, at Salisbury Cathedral; they’ve repaired and automatically wound the most important astronomical clock at Hampton Court Palace; they’ve completed major work on clocks at Leeds Town Hall, Manchester Town Hall and Manchester, Durham, Hereford and Worcester Cathedrals. Their knowledge and passion proved an inspiration to the whole team.

The day we reached completion at Elizabeth Tower was a historic one – and one our team members will take pride in for the rest of their lives.

With the results of the restoration on display for all of London to see, they’ve achieved something that speaks for itself, a contribution to the UK’s heritage of which they’ll be able to remind themselves every time they walk past.

A triumph for them and for the army of people who worked to bring the project to fruition, it’s a scheme that exemplifies our commitment to our purpose as a business: proudly building Britain’s future heritage.

Our Special Projects team worked meticulously to restore the Elizabeth Tower and bring back its former glory.

Flagship restoration project scoops RIBA London Award

Mike Coleman and our Special Projects team deliver complex conservation and new build projects in heritage buildings, balancing preservation, innovation and legacy.

This year, our Annual Apprenticeship Conference included a talk about the restoration of the Elizabeth Tower.

Phase 3 delivered state-of-the-art operating theatres, modernising surgical facilities to support high-quality, modern care

Administration Apprentice, Maisie Woods, a resident of Bridgwater, is amongst the ten apprentices employed by Sir Robert McAlpine currently working at Agratas

Agratas, Tata Group’s global battery business, has announced the successful completion of the steel frame for its new facility in Bridgwater, Somerset.