- Client: Strategic Estates

- Sector: Heritage & Special Projects

- Region: London

- Services: Digital Construction, Special Projects, Construction

Preserving history: Restoring the iconic Elizabeth Tower

Our Special Projects team worked meticulously to restore the Elizabeth Tower back to its former glory.

Our Sir Robert McAlpine Special Projects team, renowned for its expertise in handling complex heritage and conservation projects, worked meticulously to restore the Elizabeth Tower and bring back its former glory.

For more than 160 years, the Elizabeth Tower, also known as Big Ben, has stood tall as the nation's timekeeper. However, the passage of time, combined with the adverse effects of pollution, weather, and war had taken its toll on this iconic London landmark.

It was clear that significant restoration work was needed to preserve the Tower for future generations. Our highly experienced Sir Robert McAlpine Special Projects team had the skills, knowledge and expertise required to deliver this complex project.

With all the logistical and security concerns that come with working inside the Parliamentary Estate, and the inevitable public scrutiny that’s involved in repairing a national icon, construction projects don’t come much more pressured than this.

Project summary

A once in a lifetime project

The five-year programme of works to the Elizabeth Tower was the largest repair and conservation programme in the building’s history. Alongside our supply chain partners, AECOM, Currie & Brown, Lendlease, Purcell and S I Sealy, we delivered everything from the restoration of the external fabric and the clock mechanism itself, to the installation of energy efficient lighting and a much-needed lift.

We were, of course, careful to make sure that as much of the historic fabric of the building as possible was retained. Shepley Engineers and Universal Coatings salvaged most of the cast iron roof; just 20% of the tiles were replaced, and the new ones were made from recycled materials. Any tiles that couldn’t be saved were recycled. The building's ageing services were also replaced with more energy-efficient options: the Tower’s four clock faces are now illuminated by multi-coloured LEDs.

For a landmark of this importance, only work of the highest quality will suffice. Much of the restoration work was carried out off-site by leading specialists using their own workshops around the country. However, stonework specialists DBR Ltd and Cliveden Conservation oversaw the replacement of more than 700 replacement masonry pieces in a temporary workshop at the base of the Tower.

As well as programming our work around complex security considerations, we also needed to make sure the Tower could continue to play its preeminent role in the life of the nation. With the its striking mechanisms being carefully refurbished, we installed a temporary electronic system that allowed Big Ben to be heard on Remembrance Sunday and at New Year.

As the project neared completion, the country received the sad news of the death of Her Majesty Queen Elizabeth II. As a mark of respect, the entire site team demobilised within 24 hours. Later, they worked alongside the in-house clock mechanics and the Cumbria Clock Company to make sure the bells were ready to strike for the state funeral on 19th September 2022, contributing to a significant moment in UK history.

Safety and security on the Parliamentary Estate

Working within the Palace of Westminster presented unique security challenges. We had to plan well in advance to bring anything onto site, whether that was people or materials. This rendered even the most routine task a substantial undertaking.

Early on in the project, we used BIM models to convey to people involved in the scheme who did not have construction backgrounds how the site would change and evolve over time, and what the implications would be for the safety and security of the Parliamentary Estate. This topic remained at the forefront of the team’s minds throughout the works, and we revisited it regularly, making sure our measures for reducing our impact on the Estate remained up-to-date and effective.

In March 2020, Covid-19 hit the UK, and for a number of reasons the Elizabeth Tower project was affected more than most. Not only were we working in a building with a footprint of just 12 square metres, our operations also brought our teams into close proximity with members of both Houses of Parliament and their staff. When we were able to reopen the site, we ensured rigorous Covid protocols were in place to protect the nation’s legislators as well as our own people.

An exceptional team culture informed by pride in the job

Throughout these challenges, we maintained an excellent working relationship with client body Strategic Estates. They shared the project team’s passion for every aspect of the job, joining us on visits to Cumbria to view the clock restoration, and they are as immensely proud of the resulting building as we are. Importantly, under the NEC contract, cost and change were monitored closely in real time, as the Tower revealed its secrets. This meant that change was managed as it happened, with the team agreeing on how to handle it with the client in an open and transparent manner.

The pride of everyone who worked on the Tower was evident at every turn. With each member of the team aware that this might go down as the project highlight of their career, the atmosphere on site was electric, every person’s passion for their work tangible in the way they performed their activities and supported one another. This was exhibited in the way we handled the replacement of the 1,296 pieces of hand-blown glass in the Tower’s clock dials: everyone on the team was given the opportunity to install one of these pieces, symbolising their vital contributions to this remarkable project.

The scheme brought together specialists not just from all over the country, but all over the world. Working in close quarters, large contractors and individual artisans were able to learn from each other’s experience and expertise, exhibiting a level of care for their work that inspired everyone who came into contact with them. Small wonder that in some of our staff the project sparked a zeal for the heritage sector. With several of our team members going on to obtain qualifications in historic construction and manage other heritage projects, the Elizabeth Tower scheme has left an enduring legacy within SRM.

Using digital technology to restore Elizabeth Tower

Our ability to meet the requirements of BIM Level 2 saw us deploying some innovative solutions on this complex heritage project, improving the old with the benefits of the new. Online asset tracking platform Zutec played a crucial role in our efforts to restore the Tower to its former glory, preserving its history for centuries to come.

The platform allowed our team to track each component making up the Tower, including the 3,433 unique pieces of cast iron on its roof. This in turn meant that they could easily check on the progress of restoration work and make sure that every piece of the Tower’s historic fabric was returned to its original location, saving time and helping us meet the exceptional standards of quality required on this most prestigious of projects.

Early on in the project, we held a series of workshops in which we customised Zutec’s form templates to take into account the artisan expertise of the specialists on the scheme. This, along with the user-friendliness of the platform, empowered the on-site experts to take ownership of the asset tracking process, helping us all to get as much out of it as possible.

The platform also allowed us to create an asset list of maintainable architectural features on the site, a vital tool on historic buildings like Elizabeth Tower. With the project finished, our client chose to renew the platform license, recognising its value for future work on the estate and for monitoring the ageing of historic materials.

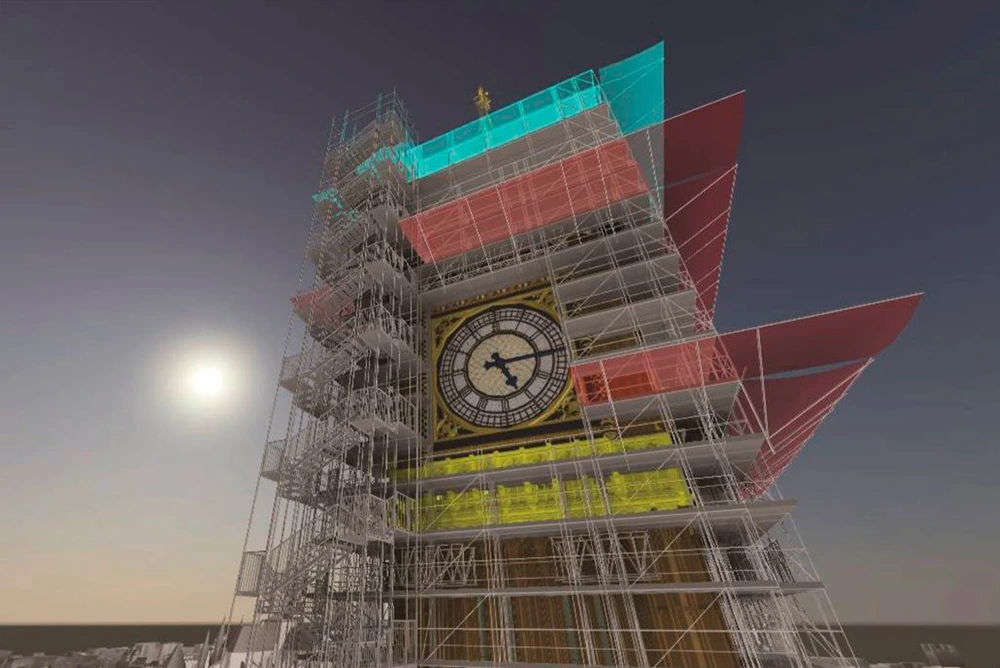

This wasn’t the only way in which we, and by extension our client, benefited from cutting-edge digital construction techniques. To allow the restoration of the Tower to be carried out, our in-house McAlpine Design Group worked alongside PHD Access to develop a 98m scaffold enveloping almost the entire structure. To protect the Tower from damage caused by extra loads being imposed on it, the scaffold had to be freestanding and self-supporting. It was composed of 24,000 separate elements and took six months to erect, in an operation that involved 320 individual vehicle movements.

To make this enormously complex structure a success, we created a detailed 3D model as a tool for design coordination, giving the whole team an insight into how the scaffold would work and how it should be installed, something that became particularly important at the level of the belfry, where the scaffold was to pass through the Tower’s cast iron frame once its roof tiles had been removed.

-

Digital Construction

Find out moreWe invest in industry-leading software and mobile applications. So we can deliver cost efficiencies and top performance - each and every time.

Photography: UK Parliament, Jessica Taylor

-

Special Projects

Find out moreOur Special Projects team is dedicated to providing complex heritage restoration schemes with the technical excellence and expertise they deserve.

Special projects

-

![Sainsbury Wing entrance on a sunny afternoon]() Read more about

Read more aboutNational Gallery

The National Gallery’s transformation project marked a pivotal moment as it celebrated its bicentennial.

Sectors: Heritage & Special ProjectsRegion: London -

![Exterior view of120 Oxford Street in London]() Read more about

Read more about120 Oxford Street

Remodelling the Plaza Shopping Centre on Oxford Street to create two new shops.

Sectors: Retail, Leisure, CommercialRegion: London -

![Exterior view of Maggie’s Barts, designed by Steven Holl]() Read more about

Read more aboutHeritage and complex projects expertise delivers Maggie’s Barts

Our Special Projects delivered this technically complex healthcare project within live hospital campus and protected it’s Grade I listed neighbours.

Sectors: HealthcareRegion: London